Technology is growing rapidly across the globe. Most industries have embraced technology to improve their effectiveness and increase productivity this improves their competitiveness in the industry. Robots, which are as a result of technology, are being utilized heavily in the manufacturing industry.

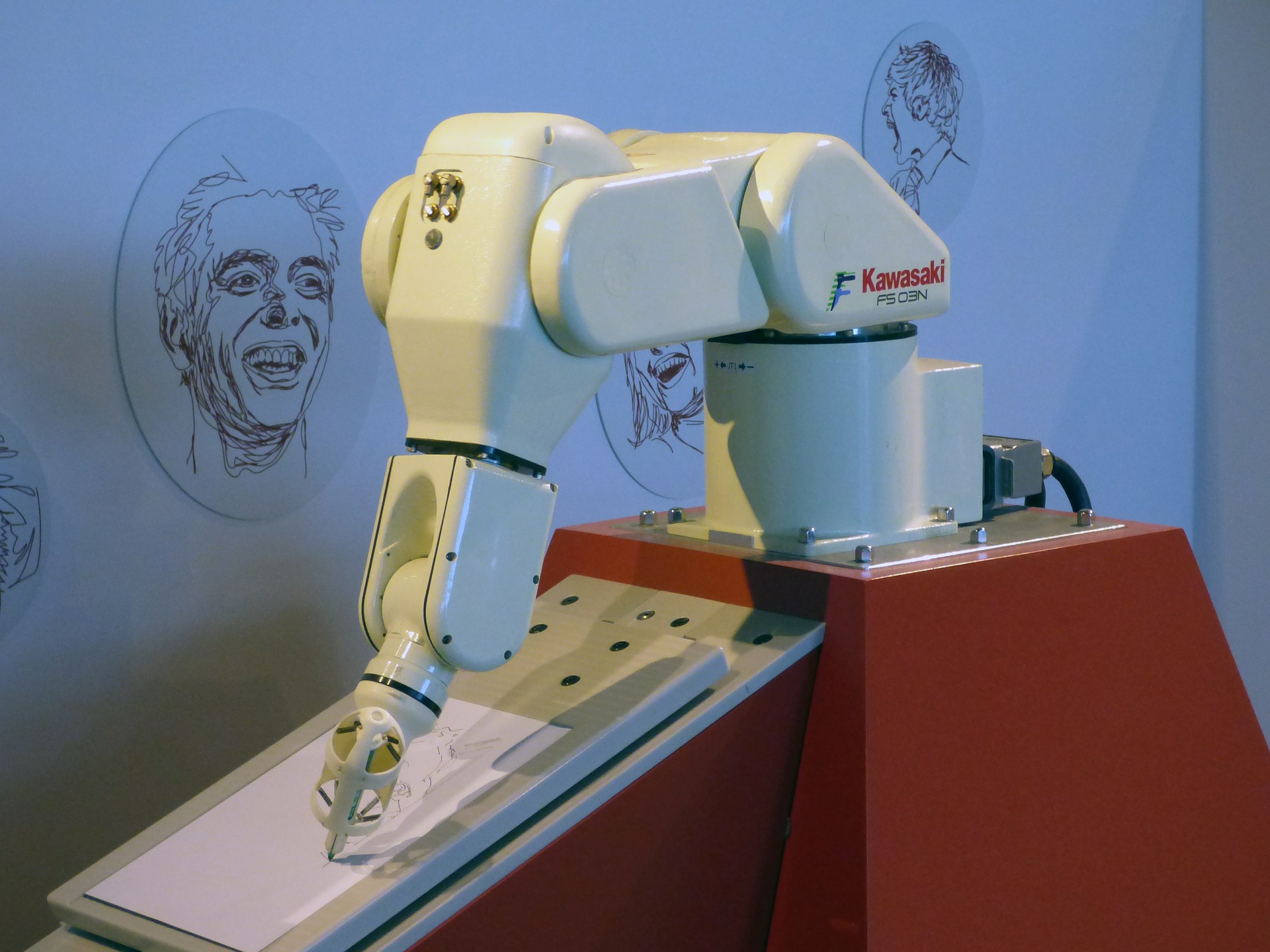

Robot arms are among other robots being utilized in the industry. A robotic arm is a programmed mechanical arm with features and functions similar to those of a human arm. This arm can automate most of tasks being carried out in the industry. Some of those tasks include: Picking and placing; painting and polishing; assembling; lab analysis; packaging and palletizing; and screwdriving.

Characteristics of robot arms

Easy and fast set-up. Most robotic arms are programmed in a way that operators with little or no programming experience are able to set them up and operate them easily.

Are flexible. Robot arms can perform different tasks. This is made possible by its easy programming and design of the robot. In most cases the operator just need to easily move the arm to the desired way points and use the correct arrow keys that will ensure the robot performs the function at hand.

Easy programming. Robot arms are programmed in a way that the user can easily operate it. Basic procedures provided to the operators are easy to apply.

They are agile. For the robot arms to meet the changing trends/demands and remain competitive, they are produced in a way that they can be easily moved. These robots do not occupy a lot of space since they are small in size. Therefore they can be easily moved from one place to another and allow for deployment.

Easy to update. With more innovations and changes in the manufacturing industry, robot arms are programmed in a way that they can be easily updated to meet the demands in the market.

Advantages of robot arms

They are accurate and provide high quality output. Due to the computerized control and proper programming of a robotic arm, they are able to perform tasks well by accurately following the programmed instructions. This provides little room for mistakes hence the end product is of high quality.

They are fast and efficient. With the computerized control, a robot arm is able to follow the programmed instructions easily and faster. Therefore, the amount of time that a human would have taken when thinking of the next procedure is covered up. This increases the rate of production in the industry.

Ability to work in hazardous environments. The mechanical nature of robots enables them to perform dirty, dull and dangerous tasks that humans cannot perform. This makes the company utilizing this robot more competitive as its production process is not limited to such issues.

Less interference. Humans get bored and tired easily especially when performing similar tasks repetitively and when working for long hours. Robot arms are not affected by the length or repetitiveness of a task; hence their level of productivity is high all times. The quality of the output is thereby maintained.

Cut the cost of hiring many employees. With the flexibility of a robot arm to perform different tasks, the personnel required to perform these tasks are reduced. Additionally, due to their easy programming, the manufacturing industry does not require frequently outsourcing professional programmers to perform certain tasks.

Reduction of waste and better saving. Due to the accuracy of the robot arms, the amount of waste of the raw materials being used is highly reduced. This consequently reduces the cost of production and increases the profit to the industry due to the high utilization of the raw materials.

Allows for better space utilization. As discussed earlier, robot arms do not occupy a lot of space. This creates space that can be utilized to perform other tasks thereby maximizing on the profits of the organization.

From the above discussion, it is evident that well developed robot arms are relevant to the manufacturing industry. Embracing this technology is a major step to maximizing or increasing the profits of the industry.