When a layer of ink is applied over a screen in order to produce a design, it is known as screen printing. Each end result requires a specific design to be made and this method of printing has multiple uses. Screen printing has seen it’s popularity soar in recent years because it’s a cost friendly method of printing while there are an increasing number of applications for this form of printing. Essentially, any surface that is flat can be used for printing. Not only can screen printing be done on a wide variety of surfaces, but it also allows you to use a range of printing materials, which means the creative possibilities are endless.

Origins

The technique of screen printing was first invented by the Chinese approximately 2000 years ago. They stretched human hair across a wooden frame, forming a screen. On this, a stencil made of leaves was attached, stuck on in different shapes. In later years, the Japanese used the same process, but using woven silk to make the mesh while lacquer replaced leaves to make the stencil. In fact, the silk screen printing machine gets it’s name from the Japanese use of silk in screen printing all those years ago!

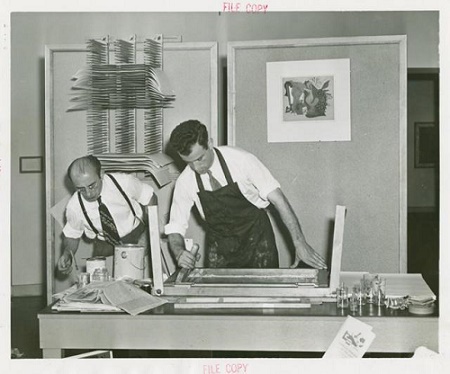

In 1907 Samuel Simon was the first man to patent the first industrial screen printing process. Today, thanks to technology, the process of screen printing has become far more advanced than the original methods and screen printing is commonly used for printing a wide range of objects including CD covers, tee shirts, advertisements on buses, printed fabrics, signs and advertisements on flyers. Even the dial on your watch has been screen printed.

Source: Fast Codesign

Growing business

According to IBIS World’s research, the custom screen printing market is a growing one and since 2012 especially, it has been booming. Most firms in this sector tend to be small, regional operators which means that there is no one company that is the leader in this particular market. In fact, the research suggests that in 2015, the top companies in the custom screen printing industry accounted for less than 5% of total revenue.

Uses of screen printing

Fabric

One of the biggest applications of screen printing is in the textile industry, printing tee shirts with designs on them, for example. Screen printing can be used to print graphics and designs on fabrics such as silk, polyester, cotton and organza. Once printed, the fabric is then converted into the final product such as shirts, dresses, skirts or children’s clothes. Any form of fabric that requires some form of printing on it can be used in screen printing. Many small scale startups often use screen printers to produce their clothing.

The process in fabric screen printing requires the design to be created and then used on screen printing. Other fabrics that can be used for screen printing include curtains, linen, cushion covers, bed sheets and upholstery.

Paper

Another industry which makes extensive use of screen printing is marketing and advertising. These sectors make use of posters, flyers and other forms of advertising that require graphics. Since advertising requires limited edition printing, it makes use of screen printing because printing electronically or digitally on a small scale are much higher than screen printing.

Souvenirs

In the sports industry, when souvenirs and collectibles are manufactured, screen printing is used. Tee shirts with the logos of sports teams are especially popular products as are key chains, caps, mouse pads and sweatshirts with graphics or team logos.

Healthcare

The strips that monitor blood sugar levels (glucose) are made using the screen printing process. The strips contain electrochemical biosensors that helps with personal glucose testing at home. Since these strips help diabetics avoid potentially life threatening sugar conditions on a daily basis, the electrode strips have to be of an extremely high quality. These single-use electrode strips are made using screen printing technology where printing is done on simple thick-film and is also called a or vapor deposition process. The process involves printing patterns onto the surface of the strip.

It only takes a quick look around you to realize several items that you come across in everyday life are made using screen printing.

Advantages

There are several advantages of using screen printing over traditional forms of printing. Firstly, because a greater thickness of ink can be used in screen printing, it allows the possibility of creating a variety of interesting printing techniques which would not be otherwise possible. Since the process of screen printing is fairly simple, a wider range of inks as well as dyes are available as compared to other printing methods. Apart from traditional inks, screen printing also allows you to use adhesive, lacquer and conductive silver. An easily adaptable printing method is always a plus for a manufacturer.

Another advantage of using screen printing is that because manufacturers can control various parameters of the process, it enables large quantities of the end result at a low cost.

Screen printing is a widely used form of printing by several industries and continues to be a popular method used by manufacturers. The process, materials required and low cost are part of the reason for its success, while the creative license that it allows is an attractive factor for many users. When it comes to bringing unique designs to life, you can’t go wrong with screen printing.

Author bio

Ann Neal is a writer with a keen interest in career, business, tech and lifestyle topics. She is passionate about music and loves to play guitar in her free time with her cute pooch listening quietly ;). Tweet her: @Ann_G_Neal